-

Why Brass Angle Ball Valves Stand Out?

Jan 03,2025

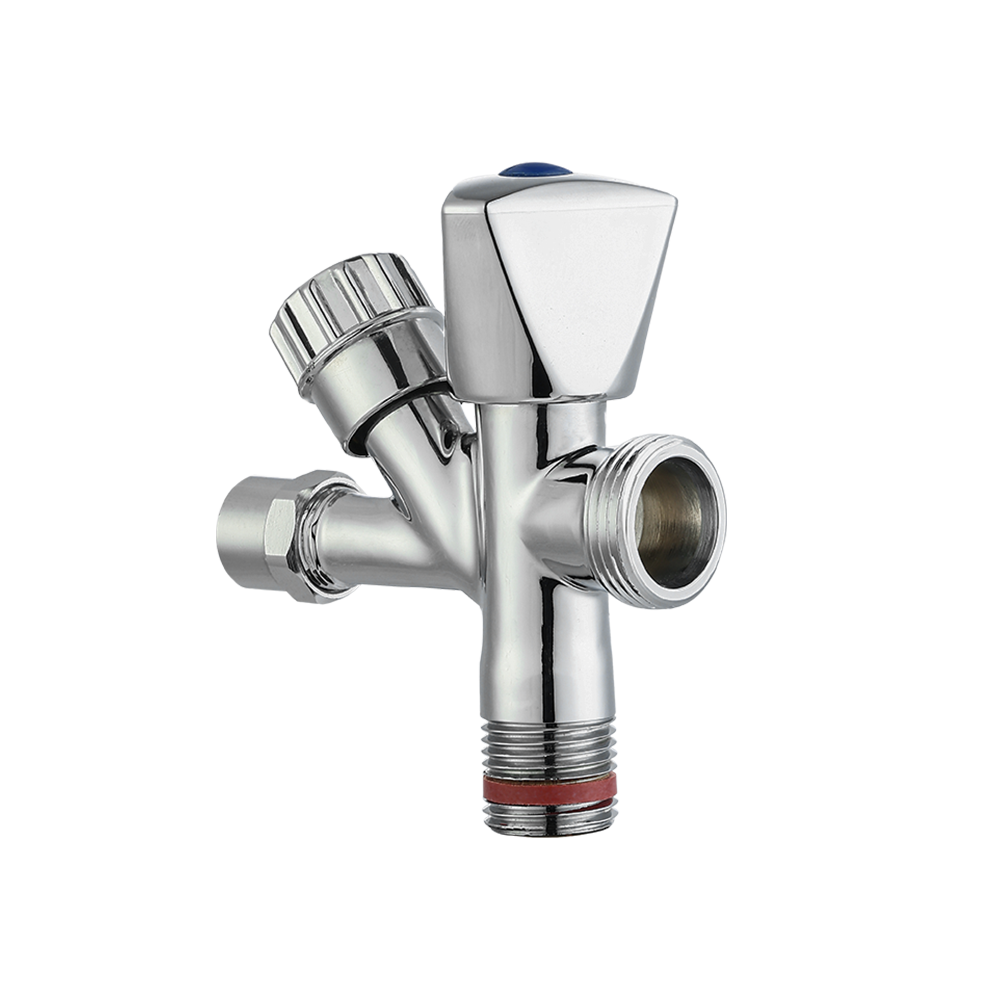

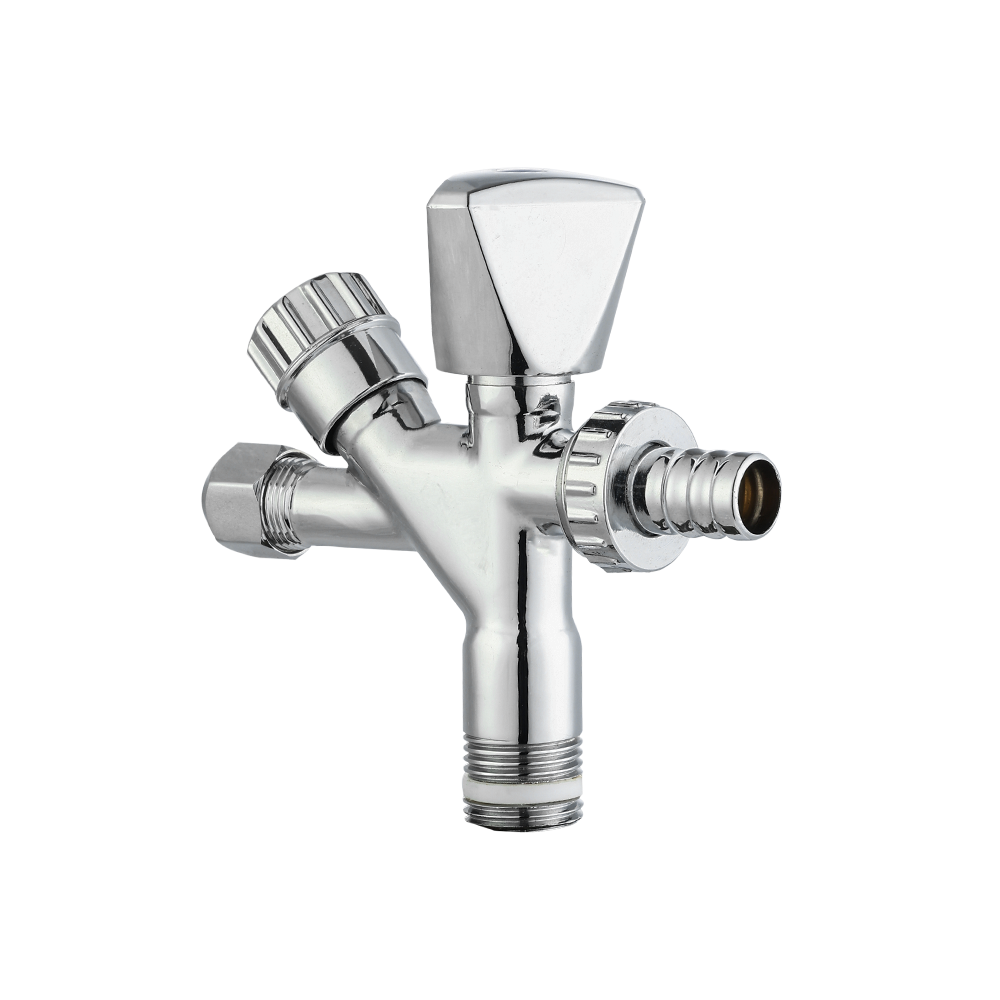

China Cheap Forged Tiny Brass Angle Ball Valve Company

In the realm of fluid control, the Brass Angle Ball Valve has emerged as a standout choice for various industries. Its unique combination of properties and performance characteristics has made it a preferred option for applications where precision, durability, and reliability are paramount. This article will explore the reasons why China Brass Angle Ball Valves stand out among other types of valves in the market.

The material composition of Brass Angle Ball Valves is a significant factor in their standout performance. Brass, being a copper alloy with zinc, offers corrosion resistance, making these valves ideal for use in environments where water, steam, or other corrosive fluids are present. The inherent antimicrobial properties of brass also contribute to the hygienic nature, which is particularly important in the food and beverage industry.

The durability of Brass Angle Ball Valves is another reason they stand out. The brass construction ensures that these valves can withstand high pressures and temperatures, which is essential in industrial applications. This durability extends their service life, reducing the need for frequent replacements and lowering maintenance costs.

Precision is a hallmark of Brass Angle Ball Valves. The ball within the valve seat provides a tight seal, ensuring that there is no leakage when the valve is closed. This precision control is crucial in applications where fluid flow must be tightly regulated, such as in chemical processing or oil and gas industries.

The versatility of Brass Angle Ball Valves is another standout feature. They are used in a wide range of applications, from water treatment and irrigation systems to industrial processes and heating, ventilation, and air conditioning (HVAC) systems. This versatility is due to their ability to handle various types of fluids and their compatibility with different system configurations.

They are known for their ease of operation. The quarter-turn operation allows for quick and easy control of fluid flow, which is beneficial in situations where rapid changes in flow are required. This feature also reduces the risk of operator error, contributing to a safer working environment.

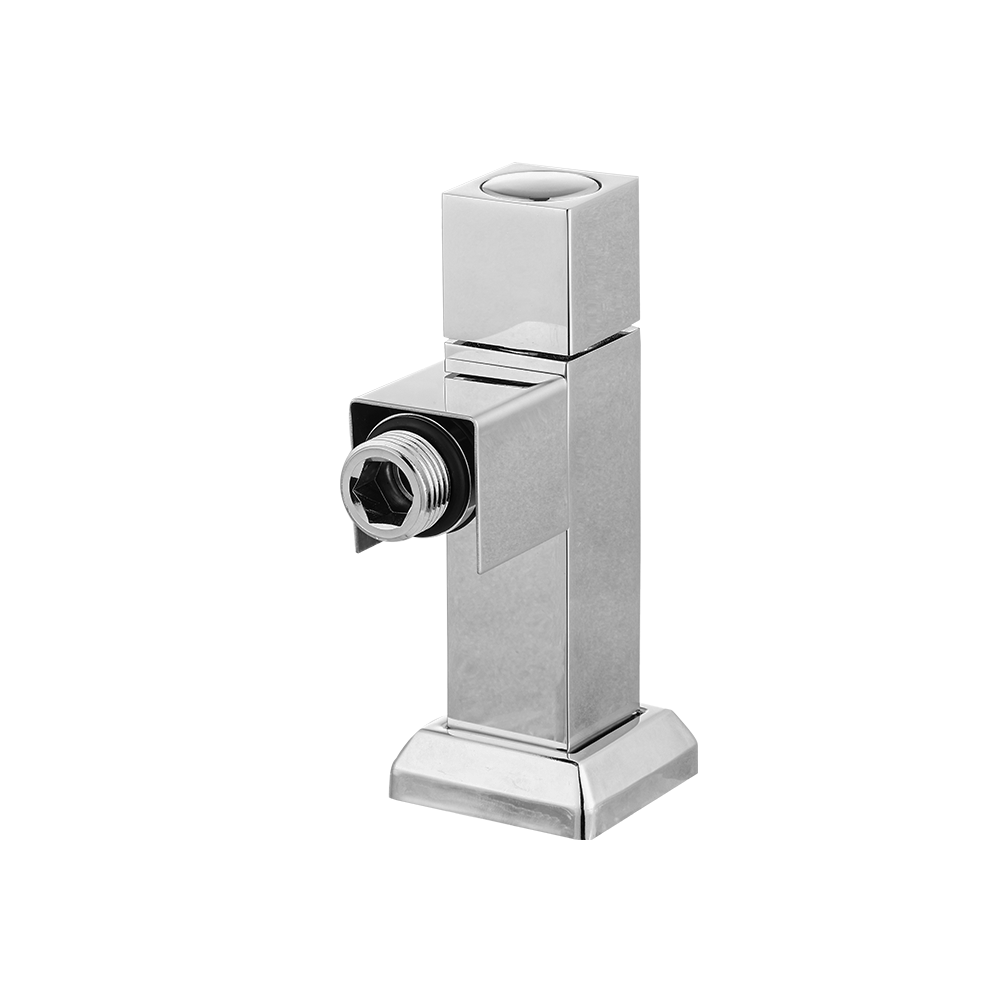

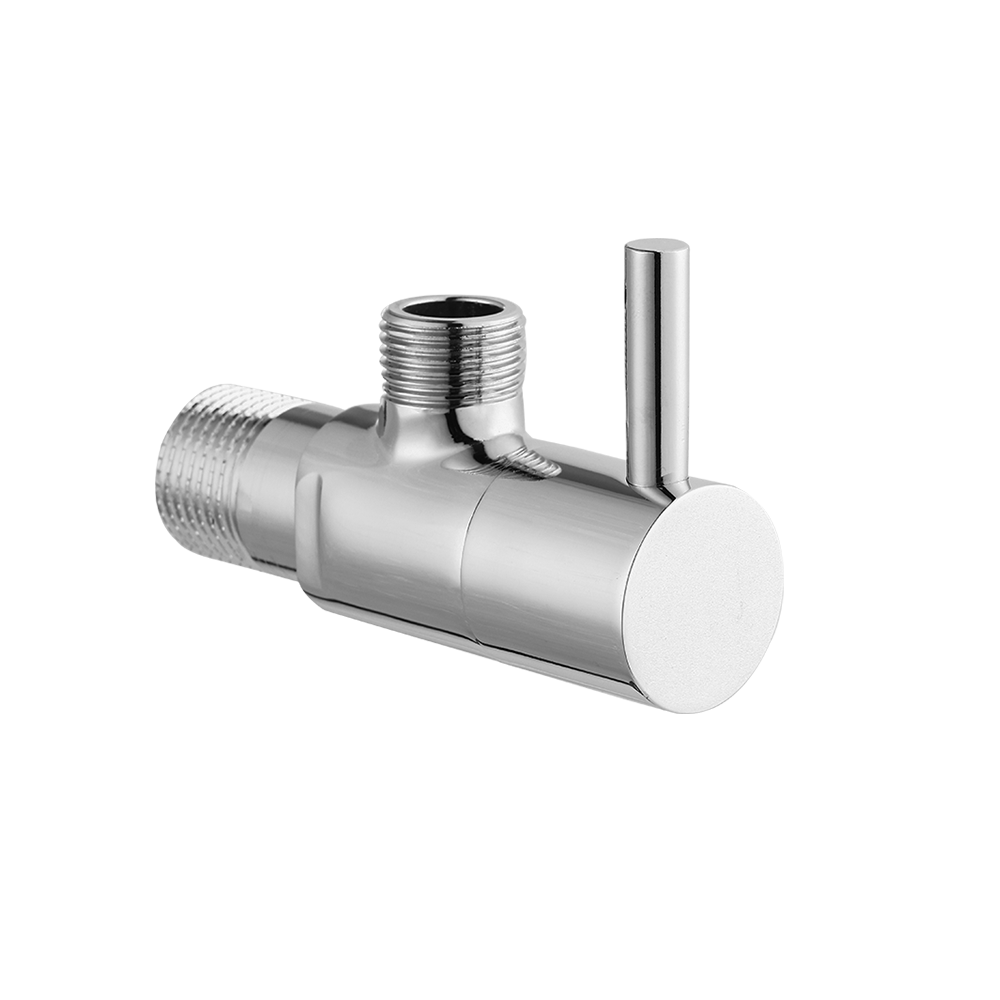

The compact design of Cheap Forged Brass Valves is another reason they stand out. They require less space than other types of valves, making them ideal for installations where space is at a premium. This compactness also contributes to their ease of installation and maintenance.

As mentioned earlier, the corrosion resistance of Brass Angle Ball Valves is a standout feature. This resistance is not only due to the material but also to the protective coatings that can be applied to the valves. These coatings further enhance their durability and suitability for use in harsh environments.

The low friction within Brass Angle Ball Valves allows for high flow rates with reduced pressure drop. This efficiency is particularly important in systems where energy conservation is a priority, as it reduces the overall energy consumption of the system.

Brass Angle Ball Valves are also known for their noise-reduction capabilities. The design of the valve and the material used help to dampen the noise generated by fluid flow, making them a preferred choice in applications where noise pollution is a concern.

The customizability of Brass Angle Ball Valves is another standout feature. Manufacturers can produce these valves in various sizes, pressure ratings, and connection types to meet the specific requirements of different applications. This flexibility allows for a tailored solution that fits the needs of the user.

Finally, the cost-effectiveness of Brass Angle Ball Valves is a standout factor. While they may have a higher initial cost compared to some other types of valves, their long service life, low maintenance requirements, and high performance make them a cost-effective choice in the long run.

The Tiny Ball Valve Company stands out for a multitude of reasons, from its material advantages and durability to its precision, versatility, and ease of operation. Its corrosion resistance, compact design, and low friction contribute to its appeal, while its noise reduction, customizability, and environmental friendliness further enhance its value. Ultimately, the cost-effectiveness of Brass Angle Ball Valves makes them a standout choice for a wide range of applications in the age of automation.

-

Understanding the Importance of Brass Angle Ball Valves in Hydraulic Systems

Dec 27,2024

China Wholesale Brass Threaded Angle Gas Ball Valve Factory

Hydraulic systems are the backbone of many industrial processes, and within these systems, the Brass Angle Ball Valve plays a pivotal role. Known for their precision and reliability, these valves are crucial components that ensure the smooth operation of hydraulic machinery. This article aims to shed light on the importance of China Brass Angle Ball Valves in hydraulic systems, highlighting their unique features and applications.

Hydraulic systems rely on the controlled flow of fluids to transmit power and perform work. Brass Angle Ball Valves are integral to this process, as they provide a means to regulate, control, and direct the flow of hydraulic fluids. Their design allows for a tight seal, preventing leaks and ensuring that the system operates efficiently. The use of brass as a material offers additional benefits, such as resistance to corrosion and the ability to withstand high pressures, which are common in hydraulic applications.

One of the primary advantages of Brass Angle Ball Valves is their durability. Brass is a strong and malleable metal that can be shaped into precise angles, which is essential for the valve's function within the hydraulic system. Additionally, brass is less prone to corrosion, which means that Brass Angle Ball Valves can operate in a wider range of environments without the risk of damage or failure. This durability extends the lifespan of the valve, reducing maintenance costs and downtime for businesses.

The precision of Brass Angle Ball Valves is another key advantage in hydraulic systems. The ball within the valve can be rotated to various positions, allowing for precise control over the flow of fluid. This precision is critical in applications where the force and speed of hydraulic actuators need to be finely tuned, such as in manufacturing machinery or construction equipment. The ability to control the flow with such accuracy is a testament to the engineering behind Brass Angle Ball Valves.

Brass Angle Ball Valves are not limited to a single type of hydraulic system. Their versatility allows them to be used in a variety of applications, from heavy machinery to small-scale hydraulic tools. This adaptability is due to the valve's design, which can be customized to fit different system requirements. Whether it's a large industrial press or a compact hydraulic cylinder, Brass Angle Ball Valves can be relied upon to perform their function effectively.

Maintenance is a critical aspect of any industrial system, and Wholesale Brass Gas Ball Valves are designed with this in mind. Their construction allows for easy disassembly and cleaning, which is essential for preventing blockages and maintaining ideal performance. The use of brass also means that the valves are less likely to corrode, reducing the need for frequent replacements and reducing maintenance costs.

Safety is a paramount concern in any industrial setting, and Brass Angle Ball Valves contribute to this by providing a secure means of controlling fluid flow. The tight seal provided by these valves helps to prevent leaks, which can be a significant hazard in hydraulic systems. Additionally, the valve's design allows for the safe release of pressure, reducing the risk of accidents and ensuring the safety of workers.

In today's environmentally conscious world, the materials used in industrial components are under scrutiny. Brass Threaded Ball Valve Factory, being made from brass, are a more sustainable choice compared to valves made from other metals. Brass is a recyclable material, and its use in valves contributes to a circular economy, reducing waste and the environmental impact of manufacturing.

As technology advances, so too does the design and functionality of Brass Angle Ball Valves. With the integration of smart technologies, these valves are becoming more connected and responsive, allowing for real-time monitoring and control. This evolution will further enhance their importance in hydraulic systems, making them even more indispensable in the future of industrial automation.

The importance of Brass Angle Ball Valves in hydraulic systems cannot be overstated. Their durability, precision, versatility, and safety features make them an essential component in a wide range of applications. With the continuous development of the industry and the complexity of hydraulic systems, the role of brass corner ball valves will only become more and more important. Understanding the importance of these valves is crucial for anyone involved in the design, operation, or maintenance of hydraulic systems, ensuring that they can harness the full potential of these indispensable components.

-

The Evolution of Brass Angle Ball Valves in the Age of Automation

Dec 20,2024

Sale Custom Brass Chrome Plated Angle Ball Valve Mini Supplier

In the age of automation, where efficiency and precision are paramount, the role of Brass Angle Ball Valves has become increasingly significant. These valves, known for their durability and reliability, have undergone a remarkable evolution to meet the demands of modern industries. This article delves into the transformation of Sale Brass Angle Ball Valves and their integral part in the automation revolution.

Brass Angle Ball Valves have been a staple in industrial settings for decades. Initially, they were used for their ability to control the flow of various fluids with precision. The brass material provided a corrosion-resistant surface, making them ideal for water, oil, and gas applications. As the initial section of our exploration, we look back at how these valves were the foundation of fluid control systems in their early days.

The evolution of Brass Angle Ball Valves has been closely tied to advancements in material science. Brass, a durable alloy of copper and zinc, has been enhanced over time to improve its resistance to wear and tear. This has allowed them to be used in more demanding environments, such as high-pressure and high-temperature applications.

With the advent of automation, the role of Brass Angle Ball Valves has expanded. They are now integrated into automated systems that require precise control over fluid flow. The development of actuators and sensors has enabled these valves to be remotely controlled, making them a key component in the automation of industrial processes.

The precision of Brass Angle Ball Valves is a critical factor in their widespread use. They offer a tight seal and can be operated with a quarter turn, making them highly reliable in automated systems where leaks and failures are not an option. This precision has been further refined through technological advancements, ensuring that they maintain their position as a preferred choice in fluid control.

The design of Brass Angle Ball Valves has also evolved to meet the specific needs of various industries. Angle ball valves are particularly useful in applications where space is limited or where the flow needs to be changed direction. This versatility in design has made them indispensable in a range of sectors, from chemical processing to food and beverage production.

As industries become more conscious of their environmental impact, Brass Angle Ball Valves have been adapted to meet these new challenges. Brass is a recyclable material, and the valves' durability means they have a long service life, reducing waste. Additionally, the valves' ability to control fluid flow with reduced energy loss contributes to energy efficiency, aligning with green initiatives.

As industries become more specialized, the demand for customized Custom Chrome Plated Angle Valves has grown. Manufacturers now offer a range of options, including different sizes, materials, and configurations, to meet the specific requirements of various applications. This customization has allowed them to remain relevant in a rapidly changing industrial landscape.

Safety is a paramount concern in industrial settings, and Brass Angle Ball Valves have been designed with this in mind. Features such as blow-out-proof stems and fire-safe designs ensure that these valves can withstand severe conditions without compromising safety.

The low maintenance and high durability of Brass Angle Ball Valves are key to their continued popularity. With fewer moving parts than other types of valves, they are less prone to failure and require less frequent maintenance, reducing downtime and costs for industries.

As Ball Valve Mini Suppliers are used in industries worldwide, there has been a push for standardization. This ensures that these valves can be easily integrated into different systems across the globe, facilitating international trade and cooperation in industrial projects.

The Brass Angle Ball Valve has come a long way from its initial applications, and its evolution in the age of automation is a testament to its adaptability and importance in modern industries. As we look to the future, the role of Brass Angle Ball Valves is likely to expand even further, as they continue to be a critical component in the quest for more efficient and precise fluid control systems.

-

Exploring the Versatility of Brass Angle Ball Valves in Various Industries

Dec 13,2024

Custom OEM Brass Angle Ball Stop Valve Maker

The world of industrial fluid control is vast and diverse, with a multitude of components playing critical roles in ensuring the smooth operation of various systems. Among these components, Brass Angle Ball Valves stand out for their versatility and reliability. These valves, crafted from brass and designed in an angle configuration, are finding applications in a wide array of industries due to their unique properties and benefits. This article aims to explore the versatility of Brass Angle Ball Valves and their significant contributions to different sectors.

Brass Angle Ball Valves are renowned for their durability and resistance to corrosion. The brass material used in their construction is a copper-zinc alloy that offers resistance to corrosion, making these valves ideal for use in environments where other materials might fail. This durability is a key factor in their widespread adoption across industries, as it reduces maintenance costs and extends the lifespan of the valves.

The design of Brass Angle Ball Valves facilitates easy installation and maintenance. Their compact size and straightforward operation mean that they can be quickly installed and maintained with reduced downtime. This is particularly beneficial in industries where uptime is critical, such as in power generation or water treatment facilities.

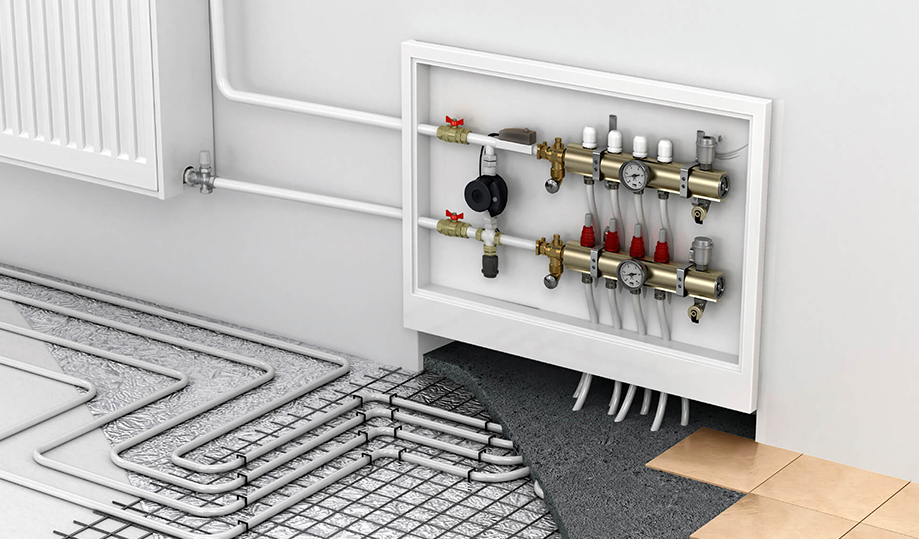

In the plumbing and heating industry, Brass Angle Ball Valves are indispensable. They are used to control the flow of water in heating systems, ensuring efficient heat distribution. Their ability to withstand high temperatures and pressures makes them ideal for these applications. Additionally, their angle design allows for easy integration into existing systems without the need for extensive modifications.

The food and beverage industry requires valves that can handle a variety of fluids, including those that are acidic or alkaline. Brass Angle Ball Valves meet these requirements, as brass is resistant to many chemicals and can be easily cleaned and sanitized. This makes them suitable for use in processing lines, where hygiene and product quality are paramount.

Pharmaceutical manufacturing also relies on Brass Angle Ball Valves for their precision and reliability. These valves are used in the control of various fluids during the production of drugs, ensuring that the correct dosages are mixed and dispensed. The non-reactive nature of brass is particularly important in this industry, as it prevents contamination of pharmaceutical products.

Environmental control systems, such as those found in greenhouses or climate-controlled facilities, often utilize OEM Brass Angle Stop Valves to regulate the flow of water and other fluids. These valves help maintain the desired temperature and humidity levels, which are critical for the growth of plants or the preservation of sensitive equipment.

The integration of Brass Angle Ball Valves with automation systems is another area where their versatility shines. These valves can be easily connected to actuators, allowing for remote control and automation of fluid flow. This is particularly useful in industries where manual operation is not feasible or where precise control is required.

In industrial processes, energy efficiency is a key concern. Brass Angle Ball Valves contribute to this by providing a means to control fluid flow with reduced energy loss. Their tight seals and efficient operation ensure that energy is not wasted through leaks or excessive pressure drops.

Safety is paramount in high-pressure applications, such as in oil and gas refineries. Brass Angle Ball Valves are designed to handle high pressures without failure, making them a safe choice for these critical applications. Their robust construction and reliable operation help prevent accidents and ensure the safety of workers and equipment.

The versatility of Brass Angle Ball Valves is evident across a broad spectrum of industries. Their durability, precision, and adaptability make them an essential component in fluid control systems worldwide. As industries continue to evolve and new challenges arise, the demand for Brass Angle Valve Makers is expected to grow. These valves offer a robust solution to complex fluid management, ensuring that they remain a key player in the advancement of industrial technology.

-

A Deep Dive into the Design and Function of Brass Angle Ball Valves

Dec 06,2024

Sale Cheap Polished Brass Angle Ball Hose Valve Stop in China

In the realm of fluid control, the Brass Angle Ball Valve stands as a stalwart choice for its durability and reliability. This article delves into the intricacies of the design and function of these valves, examining their role in various industries and applications. The Sale Brass Angle Ball Valve, with its unique angled design, offers a range of benefits that make it a preferred option for controlling the flow of liquids and gases.

The design of a Brass Angle Ball Valve is a blend of form and function. The brass construction provides a robust and corrosion-resistant material that can withstand the test of time. The angled body of the valve allows for a compact installation, making it ideal for tight spaces where a straight valve would not fit. The ball within the valve is drilled with ports and seats, which control the flow when the handle is turned. This design ensures a tight seal, preventing leaks and maintaining pressure.

The functionality of a Brass Angle Ball Valve is centered around its ability to control flow with precision. When the handle is turned 90 degrees, the valve is fully open, allowing fluid to pass through without restriction. Conversely, when the handle is turned to the closed position, the ball within the valve rotates to block the flow, creating a secure seal. This simple yet effective mechanism makes the Brass Angle Ball Valve a popular choice for applications requiring precise control.

Brass Angle Ball Valves are employed across a spectrum of industries due to their versatility. In the plumbing sector, they are used to control water flow in residential and commercial settings. Their angled design allows for easier installation in confined spaces, such as under sinks or in tight pipe clusters. In industrial settings, these valves are used in processes that require the control of chemicals, gases, and other fluids. The brass material is particularly suited for applications involving corrosive substances, as it resists corrosion better than many other metals.

One of the key benefits of Cheap Polished Brass Angle Stops is their low maintenance requirements. The brass construction is not only durable but also resistant to tarnishing and corrosion, which means that these valves can operate effectively for extended periods without the need for replacement. Regular inspection and lubrication of the valve's stem can further extend its lifespan, ensuring continued performance.

The advantages of using Brass Angle Ball Valves are manifold. Their compact design allows for easy installation in spaces where other valves might not fit. The brass material offers corrosion resistance, making these valves suitable for a wide range of fluids. The ball mechanism provides a smooth operation and a reliable seal, reducing the risk of leaks. Additionally, the angled design can help to reduce pressure surges, which can be particularly beneficial in high-pressure applications.

While Brass Angle Ball Valves offer numerous benefits, there are also considerations to keep in mind. Brass materials, while durable, are more expensive than other materials such as plastic or cast iron. Additionally, while brass is resistant to many forms of corrosion, it may not be suitable for all types of fluids, particularly those that are highly corrosive. It is essential to select the appropriate valve material for the specific application to ensure longevity and performance.

The technology behind Brass Angle Ball Valves is continually evolving. Advances in manufacturing processes have led to more precise ball and seat designs, improving the sealing capabilities of these valves. Additionally, the development of new materials and coatings can enhance the corrosion resistance of brass, broadening the range of applications for these valves.

The Angle Hose Valve in China, with its angled design and brass construction, offers a reliable and efficient solution for fluid control in various applications. Its durability, ease of operation, and precision make it a popular choice in industries ranging from plumbing to chemical processing. As technology continues to advance, the capabilities and applications of Brass Angle Ball Valves are likely to expand, further solidifying their place in the world of fluid control.

-

Impact of OEM Brass Angle Valves on Water Efficiency And Sustainability

Nov 29,2024

Custom OEM Brass Angle Ball Valve Price

In the quest for sustainable water management, the role of OEM Brass Angle Valves cannot be overstated. These precision-engineered components are integral to the efficiency and sustainability of water systems across various sectors. As the demand for water conservation and efficient distribution grows, OEM Brass Angle Valves have emerged as a key solution, offering reliability, durability, and performance that are essential for the future of water management.

OEM Brass Angle Valves are specifically designed and manufactured to meet the unique specifications of original equipment manufacturers. These valves are crafted from high-quality brass, which is known for its corrosion resistance, strength, and ability to withstand high pressures. The use of brass also ensures that these valves are compatible with a wide range of water treatment chemicals, making them suitable for various applications.

One of the primary impacts of OEM Brass Angle Valves on water efficiency is their ability to control water flow with precision. By providing a tight seal and reducing leakage, these valves reduce water waste, which is crucial in maintaining efficient water distribution networks. The precision engineering of them ensures that they can be easily adjusted to control the flow rate, pressure, and direction of water, which is vital for optimizing water usage in different scenarios.

Sustainability is at the core of OEM Brass Angle Valves' design. The use of brass as the primary material contributes to the sustainability of these valves, as brass is a recyclable metal that can be reused without losing its properties. This characteristic not only reduces the environmental impact of manufacturing but also supports the circular economy. Additionally, the durability of brass means that they have a long service life, reducing the need for frequent replacements and further contributing to sustainability.

Custom Brass Angle Ball Valves are used in a variety of applications, from domestic plumbing systems to industrial water management. In residential settings, these valves help in conserving water by ensuring that there are no unnecessary leaks or wastage. In commercial and industrial applications, they play a critical role in maintaining efficient water systems, which can result in significant cost savings and reduced environmental impact.

The benefits of using OEM Brass Angle Valves extend beyond water efficiency and sustainability. They also offer resistance to wear and tear, reducing the need for frequent maintenance and replacement. This not only saves costs but also reduces downtime in industrial processes where water management is crucial.

The ongoing advancements in valve technology have led to innovations that further enhance the performance of OEM Brass Angle Valves. For instance, the incorporation of smart sensors and actuators in these valves allows for remote monitoring and control, improving the overall management of water systems. These smart valves can detect leaks, adjust pressure, and even shut off in case of emergencies, ensuring a higher level of efficiency and safety.

Despite their numerous benefits, OEM Brass Angle Valves face challenges such as the need for regular maintenance and the potential for wear over time. However, manufacturers are addressing these issues by developing valves with improved materials and designs that reduce friction and extend the lifespan of the valves. Additionally, the use of advanced coatings can protect the brass from corrosion, further enhancing their durability.

As the world moves towards more sustainable practices, the demand for Brass Angle Valve Prices is expected to grow. These valves are not only essential for water efficiency but also for meeting the increasing global demand for clean and safe water. The future of them lies in their ability to adapt to new technologies and continue to provide high-performance solutions for water management.

In conclusion, OEM Brass Angle Valves are a critical component in the pursuit of water efficiency and sustainability. Their precision engineering, durability, and adaptability make them an essential part of modern water management systems. As technology continues to evolve, OEM Brass Angle Valves will play an increasingly important role in ensuring that our water resources are used efficiently and sustainably for generations to come.

-

OEM Brass Angle Valves Ensure High Performance In Water Management

Nov 22,2024

Custom OEM Brass Angle Stop Valve Manufacturer

Water management is a critical aspect of modern infrastructure, and the efficiency of this system is heavily reliant on the quality and performance of its components. Among these components, OEM Brass Angle Valves play a pivotal role in ensuring the high performance of water management systems. These valves, manufactured to meet the specific requirements of original equipment manufacturers (OEMs), are designed to withstand the rigors of various applications, from residential plumbing to large-scale industrial processes. This article delves into the importance of OEM Brass Angle Valves in water management and how they contribute to the overall efficiency and reliability of these systems.

OEM Brass Angle Valves are engineered to meet the precise specifications of OEMs, ensuring that they integrate seamlessly into a wide range of water management systems. These valves are known for their durability, corrosion resistance, and ability to maintain a tight seal, which are essential characteristics for any water management component. The use of brass as the primary material for these valves offers several advantages, including high strength, ideal heat resistance, and resistance to wear and tear.

The quality of OEM Brass Angle Valves is paramount in ensuring the longevity and reliability of water management systems. High-quality valves are less prone to leaks, which can result in water wastage and potential damage to infrastructure. Additionally, they are more resistant to the corrosive effects of water, which can be particularly aggressive in certain environments. This resistance extends the life of the valves and reduces the need for frequent replacements, thereby lowering maintenance costs and downtime.

OEM Brass Angle Valves are designed to be versatile, allowing for easy integration into a variety of water management systems. Whether used in domestic settings, commercial buildings, or industrial facilities, these valves provide a reliable means of controlling water flow. Their compact design and ability to be installed at various angles make them ideal for use in tight spaces or where space is at a premium.

The performance benefits of Custom Brass Angle Stops are numerous. They offer precise control over water flow, which is crucial for maintaining pressure levels in plumbing systems. This precision also helps in conserving water by preventing unnecessary wastage. Furthermore, the smooth operation of these valves reduces noise, which is particularly beneficial in residential settings where noise pollution can be a concern.

One of the key advantages of OEM Brass Angle Valves is their resistance to corrosion. Brass is a durable material that does not react with water, making it an ideal choice for valves that will be in constant contact with water. This resistance to corrosion not only prolongs the life of the valve but also ensures that the water passing through remains clean and free from contaminants that could be introduced by a corroding valve.

The durability of OEM Brass Angle Valves is another factor that contributes to their high performance in water management. Brass is a strong material that can withstand high pressures and temperatures, making these valves suitable for a wide range of applications. Their ability to maintain a tight seal over time ensures that they continue to perform at an ideal level, even under demanding conditions.

In today's environmentally conscious world, the sustainability of materials used in manufacturing is of importance. OEM Brass Angle Valves, made from brass, a recyclable material, contribute positively to the environment by reducing waste and the need for new raw materials. This sustainability aspect is particularly important in the context of water management, where the conservation of resources is a key concern.

In conclusion, OEM Brass Angle Valves are indispensable in the realm of water management. Their high performance, durability, and reliability make them a preferred choice for OEMs looking to ensure the efficiency and longevity of their water management systems. By selecting high-quality Brass Angle Stop Valve Manufacturers, manufacturers can provide their customers with products that not only meet their immediate needs but also contribute to the sustainability and environmental responsibility of their operations. As the demand for efficient and sustainable water management solutions continues to grow, the role of OEM Brass Angle Valves will remain crucial in meeting these challenges.

-

The Advantages of OEM Brass Angle Valves in Commercial Plumbing Systems

Nov 15,2024

Custom OEM Chrome Plated Brass Angle Hose Valve Manufacturer

In the realm of commercial plumbing systems, the choice of valves can significantly impact the efficiency, durability, and overall performance of the system. OEM Brass Angle Valves have emerged as a preferred option for many contractors and facility managers due to their numerous advantages. These valves, manufactured to meet the specific requirements of original equipment manufacturers (OEMs), offer a blend of quality, reliability, and customization that is hard to match. This article will delve into the benefits of using OEM Brass Angle Valves in commercial plumbing systems, highlighting their importance in ensuring the smooth operation of these critical infrastructures.

Valves are integral components of any plumbing system, controlling the flow of water and other fluids. In commercial settings, where high volumes of water are used and the plumbing system is subjected to constant stress, the choice of valves becomes even more critical. OEM Brass Angle Valves, with their precision engineering and material, stand out as a top choice for these demanding applications.

Advantages of OEM Brass Angle Valves. They are renowned for their durability. Brass is a robust material that can withstand high pressures and temperatures, making these valves ideal for commercial use. The longevity of these valves reduces the need for frequent replacements, thereby lowering maintenance costs and downtime.

One of the key advantages of Custom Chrome Plated Angle Valves is their resistance to corrosion. Brass is less susceptible to rust and other forms of corrosion compared to other metals, ensuring that the valves maintain their integrity over time. This resistance is particularly beneficial in environments where water quality may be questionable or where the plumbing system is exposed to harsh conditions.

OEM Brass Angle Valves are engineered to precise specifications, ensuring that they fit seamlessly into the plumbing system without any leakage or misalignment. This precision is crucial in commercial settings, where even minor leaks can result in significant water waste and potential damage.

One of the primary benefits of OEM Brass Angle Valves is the ability to customize them to meet specific project requirements. Whether it's the size, shape, or additional features, these valves can be tailored to the unique needs of each commercial plumbing system, ensuring ideal performance and compatibility.

OEM Brass Angle Valves are designed with ease of installation and maintenance in mind. Their compact design and straightforward operation make them easy to install and service, reducing the time and labor required for maintenance tasks.

In commercial settings, where aesthetics can be as important as functionality, OEM Brass Angle Valves offer a sleek and professional appearance. The brass material has a natural shine that can enhance the overall look of the plumbing system.

OEM Brass Angle Valves are known for their quiet operation. The dense brass material helps to dampen the noise created by water flow, making these valves an ideal choice for noise-sensitive commercial environments.

These valves are designed to handle a wide range of temperatures, making them suitable for both hot and cold water applications. This versatility is particularly useful in commercial settings, where temperature control is crucial for various processes.

While the initial cost of Angle Hose Valve Manufacturers may be higher than that of other valve types, their long-term cost-effectiveness is undeniable. The reduced need for maintenance and replacement, coupled with their durability, makes these valves a cost-effective choice for commercial plumbing systems.

Brass is a recyclable material, and the use of OEM Brass Angle Valves contributes to a more sustainable approach to plumbing. This eco-friendliness is increasingly important in today's environmentally conscious commercial sector.

OEM Brass Angle Valves offer a range of advantages that make them an ideal choice for commercial plumbing systems. Their durability, corrosion resistance, precision engineering, and customization capabilities, among other benefits, contribute to the efficient and reliable operation of these systems. As commercial facilities continue to seek ways to enhance their operations and reduce their environmental impact, the role of OEM Brass Angle Valves in achieving these goals cannot be understated.

-

The Role of OEM Brass Angle Valves in Industrial Applications

Nov 08,2024

China OEM Polished Brass Angle Valve Stop Factory

In the vast landscape of industrial applications, precision and reliability are paramount. Among the many components that contribute to the smooth operation of industrial systems, OEM Brass Angle Valves play a crucial role. These valves, manufactured by Original Equipment Manufacturers (OEMs), are engineered to meet specific requirements and are integral to the functionality of various processes. This article will explore the significance of China Polished Brass Angle stops in industrial settings and how they contribute to efficiency and safety.

OEM Brass Angle Valves are designed to handle a variety of fluids, including water, steam, and various chemicals, making them indispensable in numerous industrial applications. Their robust construction and precise engineering ensure that they can withstand the pressures and temperatures encountered in these environments. The term "OEM Brass Angle Valve" refers to a specific type of valve that is manufactured to the exact specifications of the client, ensuring compatibility and ideal performance within the client's unique system.

Applications of OEM Brass Angle Valves. They are commonly used in plumbing and heating systems due to their ability to control the flow of water or steam with precision. They are often found in radiator systems, where they help regulate heat distribution.

In the chemical industry, OEM Brass Angle Valves are used to control the flow of corrosive substances. The brass material is resistant to many chemicals, making these valves ideal for use in chemical processing plants.

The food and beverage industry relies on OEM Brass Angle Valves for their sanitation and corrosion resistance. They are used in processing lines to control the flow of ingredients and in cleaning systems to ensure higher standards of hygiene.

Marine environments are particularly harsh on materials, and OEM Brass Angle Valves are chosen for their corrosion resistance and durability. They are used in shipbuilding for controlling water intake and discharge systems.

In the automotive industry, OEM Brass Angle Valves are used in the cooling systems of engines. Their ability to withstand high temperatures and pressures makes them a preferred choice for this application.

One of the primary advantages of OEM Brass Angle Valves is their customization. Manufacturers can produce these valves to meet the exact specifications of their clients, ensuring that they fit seamlessly into the client's system. This customization also allows for a high degree of quality control, as each valve is made to precise measurements and undergoes rigorous testing before being shipped to the client.

OEM Brass Angle Valves are also chosen for their environmental benefits. Brass is a recyclable material, and using these valves can contribute to a company's sustainability goals. Additionally, their durability means that they have a long service life, reducing the need for frequent replacements and the associated waste.

The durability of OEM Brass Angle Valves is another factor that makes them a popular choice in industrial applications. They are designed to withstand the wear and tear of daily use, reducing the need for frequent maintenance and replacement. This not only saves costs but also reduces downtime in industrial processes.

OEM Brass Angle Valves are a critical component in a wide range of industrial applications. Their precision engineering, customization options, and durability make them an ideal choice for controlling fluid flow in various environments. As industries continue to evolve and the demand for high-quality, reliable components grows, Brass Angle Valve Factory will remain a cornerstone in ensuring the smooth operation of industrial systems. By understanding the role of these valves and the benefits they offer, companies can make informed decisions that enhance their operations and contribute to a more sustainable future.

-

How Can Wholesale Brass Angle Valves Simplify Your Supply Chain?

Nov 01,2024

Wholesale Custom Brass Angle Drain Valve Supplier

In the complex world of manufacturing and construction, streamlining the supply chain is crucial for maintaining efficiency and reducing costs. One often overlooked aspect of this process is the procurement of essential components like valves. Wholesale brass angle valves, in particular, can play a pivotal role in simplifying the supply chain for businesses in various industries. This article will delve into the ways in which these valves can contribute to a more streamlined and efficient supply chain.

Streamlining the supply chain is essential for several reasons. It can result in reduced delivery times, lower inventory costs, and improved customer satisfaction. By simplifying the process of sourcing and procuring materials, businesses can focus more on their core competencies and less on logistical challenges.

Wholesale brass angle valves are a type of plumbing valve that is widely used in various applications, from residential plumbing to industrial processes. These valves are known for their durability, corrosion resistance, and ease of installation. When purchased in bulk, they offer several advantages that can simplify the supply chain.

One of the significant benefits of wholesale brass angle valves is the cost savings that come with bulk purchasing. By buying in large quantities, businesses can negotiate better prices with suppliers, resulting in substantial cost reductions.

When you purchase wholesale brass angle valves from a reputable supplier, you can be assured of consistent quality across all units. This consistency is crucial for maintaining the integrity of your products and services, as well as for meeting regulatory standards.

With a steady supply of wholesale brass angle valves, businesses can reduce the delivery times associated with procuring these essential components. This can result in faster production cycles and quicker delivery of finished products to customers.

By maintaining a bulk stock of Custom Brass Angle Valves, businesses can simplify their inventory management processes. This can result in reduced storage costs and fewer administrative tasks, allowing for more efficient use of resources.

Having a reliable source of wholesale brass angle valves allows businesses to be more flexible in their operations. They can quickly adapt to changes in demand or project requirements without having to worry about sourcing valves at short notice.

By purchasing wholesale brass angle valves, businesses can also contribute to a more sustainable supply chain. Brass is a recyclable material, and by using these valves, companies can reduce their environmental impact.

To further illustrate the benefits of wholesale brass angle valves in simplifying the supply chain, let's consider a few case studies.

A large construction company specializing in residential buildings found that by sourcing wholesale brass angle valves, they were able to standardize their plumbing systems across all projects. This not only reduced the time spent on procurement but also ensured that all homes were built to the same high standards.

In an industrial setting, a chemical plant relied heavily on wholesale brass angle valves for their process control systems. By maintaining a bulk stock, they were able to reduce downtime during maintenance and repairs, ensuring continuous operation and increased productivity.

A national plumbing supply chain faced challenges with inconsistent valve quality from various suppliers. By switching to a single source for wholesale brass angle valves, they were able to ensure uniformity across all their stores, resulting in improved customer satisfaction and reduced returns.

In conclusion, Angle Drain Valve Suppliers offer a multitude of benefits that can significantly simplify the supply chain for businesses in various industries. From cost savings to improved inventory management, these valves provide a reliable and efficient solution for procurement needs. By recognizing the value of wholesale brass angle valves, businesses can take a step towards a more streamlined and cost-effective supply chain, resulting in increased competitiveness and customer satisfaction.

-

Wholesale Brass Angle Valves Are a Wise Choice For Contractors

Oct 25,2024

Wholesale OEM Brass Angle Hose Body Valve in China

In the construction and plumbing industry, contractors are always on the lookout for materials that offer both quality and value. One such product that has gained significant attention is the wholesale brass angle valve. These valves are not only known for their durability and reliability but also for their cost-effectiveness when purchased in bulk. This article will discuss why OEM Angle Hose Valves are a wise choice for contractors.

Wholesale brass angle valves are a type of plumbing fixture designed to control the flow of water or other fluids in a system. They are typically installed at angles, which allows for easier installation in tight spaces. The term "wholesale" refers to the purchase of these valves in large quantities, often at a discounted rate compared to buying them individually.

One of the primary reasons contractors opt for wholesale brass angle valves is the cost savings. When purchased in bulk, these valves offer a significant reduction in price per unit. This cost-effectiveness is crucial for contractors who need to manage budgets carefully and ensure that they are getting value for their investment.

Wholesale brass angle valves are made from high-quality brass, which is known for its durability and resistance to corrosion. This means that these valves are less likely to leak or fail over time, reducing the need for costly repairs and replacements. Contractors can trust that these valves will perform reliably in various applications, from residential plumbing to commercial and industrial settings.

The design of wholesale brass angle valves makes them easy to install in various plumbing systems. Their angled configuration allows for a more straightforward fit in tight spaces, which can save time and labor costs during installation. Contractors appreciate this ease of installation, as it can help speed up projects and reduce overall costs.

In addition to their functional benefits, wholesale brass angle valves also offer an aesthetic appeal. The brass material has a polished look that can enhance the appearance of any plumbing system. For contractors working on high-end residential or commercial projects, the visual appeal of these valves can be a selling point.

Contractors often need valves in various sizes and types to accommodate different plumbing systems and requirements. Wholesale brass angle valves are available in a wide range of sizes and configurations, making it easy for contractors to find the fit for each job. This versatility ensures that contractors can meet the needs of their clients without having to source multiple types of valves.

The longevity of wholesale brass angle valves is another significant advantage for contractors. Brass is a material that can withstand the test of time, and these valves are designed to last for years without needing replacement. This longevity can reduce the need for ongoing maintenance and replacement costs, which is beneficial for both contractors and their clients.

One of the benefits of choosing wholesale brass angle valves is their availability. Many suppliers offer these valves in bulk, ensuring that contractors can easily source the quantities they need. This availability is crucial for contractors who need to keep projects moving without delays due to supply chain issues.

In today's environmentally conscious world, contractors are increasingly looking for materials that are sustainable and eco-friendly. Brass is a recyclable material, and Angle Body Valve in China contributes to a more sustainable plumbing industry. By choosing these valves, contractors can align their projects with environmental goals.

In conclusion, the decision to choose wholesale brass angle valves is a wise one for contractors. These valves offer a combination of cost-effectiveness, quality, and reliability that is hard to match.

-

Why Choose Wholesale Brass Angle Valves?

Oct 18,2024

Wholesale Cheap Brass Threaded Angle Stop Valve Price

In the plumbing and industrial sectors, the choice of valves can significantly impact the efficiency, safety, and longevity of a system. Among the various types of valves available, wholesale brass angle valves stand out for their durability, reliability, and aesthetic appeal. This article will explore the reasons why businesses and homeowners should consider choosing wholesale brass angle valves for their projects.

The Benefits of Brass Angle Valves. Brass is a robust material known for its resistance to corrosion and wear. Wholesale brass angle valves are designed to withstand the test of time, providing long-lasting performance in various applications. The natural properties of brass make it highly resistant to corrosion, which is a significant advantage in environments where water and other corrosive substances are present.

Brass angle valves are easy to clean and maintain, ensuring that they continue to operate efficiently with reduced downtime. Brass has a classic, polished look that adds a touch of elegance to any setting, making wholesale brass angle valves a popular choice for both commercial and residential installations.

These valves can be used in a wide range of applications, from residential plumbing to industrial processes, making them a versatile option for various projects. When purchased in bulk, wholesale brass angle valves offer a cost-effective solution for businesses looking to save on their procurement costs. Reputable suppliers often provide quality assurance, ensuring that the Cheap Brass Angle Stop Valves meet industry standards and customer expectations.

The Advantages of Choosing Wholesale. Purchasing wholesale brass angle valves allows businesses to take advantage of bulk pricing, which can significantly reduce costs compared to buying individual units. When you buy from a wholesale supplier, you can ensure that you receive a consistent product, which is crucial for maintaining uniformity in installations. Wholesale suppliers typically have a large inventory, ensuring that you have access to the brass angle valves you need, when you need them.

Some wholesale suppliers offer customization options, allowing you to tailor the brass angle valves to your specific requirements. A good wholesale supplier will have a reliable supply chain, ensuring that your orders are delivered on time and in good condition. Many wholesale suppliers provide additional support and services, such as technical assistance and after-sales service, which can be invaluable for businesses. By purchasing in bulk, businesses can reduce their inventory management overhead and streamline their operations.

When choosing a wholesale brass angle valve supplier, consider the following factors. Research the reputation of the supplier. Look for reviews and testimonials from other customers to gauge their reliability and the quality of their products. Ensure that the wholesale brass angle valves meet industry standards and are made from high-quality materials. Compare prices from different suppliers to find the value for your money.

Check the availability of the valves and the supplier's ability to meet your delivery timelines. A responsive and helpful customer service team can make all the difference in your experience with a wholesale supplier. Look for suppliers that offer warranties on their products and have a clear returns policy. Ensure that the wholesale brass angle valves are certified by relevant industry bodies, which can provide additional peace of mind.

In conclusion, choosing Threaded Angle Stop Price for your business or project can offer numerous benefits, from cost savings to quality assurance. By considering the factors outlined in this article, you can make an informed decision and select a reputable supplier that meets your needs. Remember, the right wholesale brass angle valve supplier can be a valuable partner in ensuring the success of your plumbing or industrial projects.

07

07